Case Studies

While the quality of our solutions remains consistently high, the approach we take to our customers’ needs can be immensely customizable, ensuring we efficiently and effectively deliver exactly what they require.

Sorry!

No items currently match your filtering criteria.

- Case Studies

- Shaping Returns from the End of a Product Journey into an Innovative Beginning

Shaping Returns from the End of a Product Journey into an Innovative Beginning

The Client

A leading international Small Domestic Appliance manufacturer and retailer.

Business Challenge

What if returns weren’t the end of a product’s journey – but the beginning of something innovative? SharkNinja are reimagining the product lifecycle. From designing with refurbishment in mind to engineering for recyclability, they build sustainability into how they work.

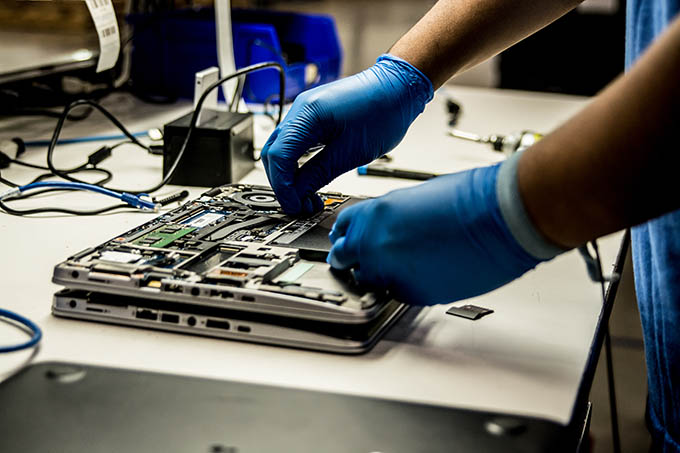

The Ingram Micro Lifecycle Solution

Supported by Ingram Micro Lifecycle, SharkNinja are transforming product returns into opportunities: reducing waste, unlocking engineering insights, and making their products more accessible to more people. It’s not just logistics – it’s a mindset shift.

The SharkNinja program takes product returns, refurbishes them, reuses them, and recycles them. It salvages around 85% of their returns.

Information is fed to SharkNinja’s engineering and other core teams relating to the problems seen on returns.

Parts harvesting is maximized for re-use in non-working units, restoring the functionality.

The program allows SharkNinja to limit negative environmental impacts by reducing and monitoring plastics and using non-biochemicals to clean products the right way. Packaging used in rekitting comprises 100% recyclable brown boxes and paper packing.

Key Solution Benefits

- 85% of product returns are recovered for re-use

- Electronic and plastic waste reduction

- Better insights into engineering and product design

- Creates product range accessible to a wider target market

- Repair costs minimized through parts harvesting

- Fully recyclable onward packaging