Are you looking for more sustainable solutions for managing your or your users’ technology when these become unwanted? Without a suitable means of disposal, products can add to the growing volume of e-waste or sit unwanted in storage. Both you and your customers are also missing out on a potential new source of financial return.

Recovery of technology provides the opportunity for the restoration of products to a good working condition, enabling reuse. These products avoid landfills and ease the pressure on manufacturing brand-new ones.

Ingram Micro Lifecycle operates trade-in and buyback programs on behalf of retailers, manufacturers, and network operators. We understand the environmental damage unused technology can do if disposed of incorrectly. As such, we seek innovative ways to recover products, extending their useful lifecycle.

In the article below, you’ll better understand how recovering technology improves the environmental impact of usage by you and your customer base.

How technology damages the environment

Technologies are released all the time that aim to improve our lives in some way or make life easier. Some are necessities, life-saving, or assistive equipment. Others are luxuries, the nice-to-haves rather than need-to-haves.

While some technology is now unavoidable for modern living, we should look to offset the impacts and reduce the negative footprint where possible. There are four main ways in which technology is harmful to the environment.

Consumption of raw materials in production

In the historical production of technology and seeking innovation, the mining of raw materials occurs in huge volumes. Manufacturing, therefore, consumes finite resources in the production process. Other industries require some of the same resources, including copper, cobalt, and lithium.

Up to 70 different chemical elements make up a smartphone, including:

- <85% ferrous and non-ferrous metals (e.g. copper, aluminium, zinc, nickel)

- 0.5% precious metals (e.g. silver, platinum, gold)

- 0.1% rare earth/special metals (e.g. europium, indium, tungsten)

- <20% other substances (e.g. cobalt, carbon, lithium)

On average, extracting over 200g of materials creates a mobile phone with an initial useful life of between 23 and 37 months.

As technology develops, striving for higher standards with better performance, pressure will increase on sourcing more diverse materials at higher volumes. Who knows what materials future smartphones will contain without preventative measures to protect finite resources?

Release of emissions during manufacturing

The manufacturing industry, as a whole, accounts for 25% of all global CO2 emissions and over half of the world’s energy usage. Not all of that comes from technology.

However, when broken down into product types, electronics do play their part. 95% of a smartphone's associated carbon emissions within its first year of life stems from manufacturing. A new laptop creates 333kg of CO2 emissions in manufacturing. 78% of the 72kg of CO2 emissions associated with a 10th-generation iPad stems from production.

Environmental impact from product use

The CO2 emissions from global technology use by enterprises is 1% of total greenhouse gases. Although that 1% may seem small by itself, the truth is that it’s equivalent to the whole carbon footprint of the UK.

Consider how many pieces of technology are within your business. How many employees have laptops, screens, and mobile phones? Are there also on-site computers and screens? What’s their refresh cycle? Data centers and internet use add to the carbon footprint of that technology. Then there’s the electricity generation to power and charge the products…

After work, you go home, use technology to unlock your front door, ask Alexa to put the lights on, adjust your Hive thermostat, make dinner, and play Fortnite or Stardew Valley. These are all technology touchpoints that are associated with carbon emissions. Of the lifetime carbon footprint of the Xbox One X, for example, 14% stems from production and 82% from product usage. Production of technology isn't always the biggest contributor to the overall lifetime carbon footprint.

End-of-life waste

Out of the four categories, this one is perhaps gaining the most public attention. From documentaries to truth-exposing articles, there's more evidence available about what happens to our technology after we discard it. The outcome is a tangible thing that we can see. The mountains of wasted technology are in front of us. The images linger of people informally burning these products and risking their health or of children picking through scraps of metal for anything valuable.

Discarded electrical equipment is known as e-waste or electronic waste. These products contain materials that are toxic to the environment or hazardous to those handling them.

There are over 347 million metric tonnes of unrecycled e-waste on the planet. The global contributions to e-waste grow every year. Small electronics, such as microwaves, vacuum cleaners, and hairdryers, make up over 32% of this waste. Telecoms, screens, and monitors equate to over 20%.

Where informal processing occurs, e-waste is a source of income. Handlers invoke dangerous methods such as open-air burning and acid baths to collect precious materials from the products, such as copper, gold, and silver. These processes release harmful substances (lead, mercury, brominated flame retardants, etc.) into the atmosphere. These can lead to neurological damage and cancer.

This e-waste will never properly break down. Instead, parts may deteriorate and pollute the environment.

Despite increased sustainability initiatives specifically tackling technology disposition, e-waste is still growing, with a record amount produced in 2022 (62 million tonnes).

What is the solution?

We’re so heavily reliant on technology and its complete integration into our lives that it’s difficult to correct. We cannot avoid the generation of unwanted technology right now, so solutions need to limit the negative impact, where possible.

Where a user has a piece of technology they no longer desire to own, recovery processes enable repurposing through lifecycle extension, supporting a circular economy.

Shifting from a linear economy to a circular economy

Historically, our use of technology has followed the linear economy model. The product follows the create, use, discard lineage when it’s no longer needed. It has one life.

Linear economy model

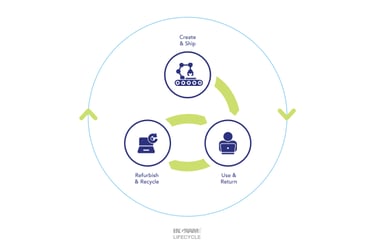

A mindset shift towards a circular economy is growing. A circular economy takes that product and tweaks its usage or restores it to a better condition ahead of reuse.

Circular economy model

Applying the circular economy model to unwanted electronics keeps the materials from landfills, responsibly recycling or reusing the materials instead. Used products take the life of a new product, avoiding the additional mining of resources and carbon footprint associated with the new product.

How recovery supports a circular economy

When we use the term ‘recovery’, we mean acquiring an electronic to extend its lifecycle or sustainably recycle components.

The product undergoes an initial assessment, determining the current condition and the level of restoration required. In some cases, the product may be beyond viable repair. At that point, it will move to disposition for responsible recycling and parts harvesting.

After condition uplift, the product can begin its new life, either with the originating owner or a new one, via recommerce.

An important note about data wiping

Compliant wiping of data-bearing products, such as mobile phones or laptops, must be part of the recovery process.

Secure wiping removes residual data and stops the breach of sensitive business information or personal identifying information.

Types of repair and refurbishment techniques

There are three levels of repair and refurbishment required after assessing a product. Level 1 is non-invasive, minor work whereas Level 3 is more intrusive, highly skilled, technical work.

Non-invasive work will be completed on the exterior of the product, such as cleaning the outer casing or buffing out minor scuffs. Invasive work involves the removal of parts, possibly replacing some components.

Below are some further examples of these processes.

DSP (Diamond Substrate Processing)

DSP is a proprietary technique that solves the problem of light scratches and scuffs. It cost-effectively boosts the cosmetic condition of devices with screens and glass backs, such as tablets and smartphones. It removes blemishes from the screen and glass back, making it easier and more pleasing to use.

As the aesthetic appeal is boosted, it increases the likelihood that the product will find a new user.

Cleaning

This can be a bigger issue for certain product types, for example, air fryers. All products being returned must be cleaned but some will need something more intensive than a wipe-down.

Each part of the product is separated for careful cleaning. This makes parts in good working order clean and suitable for re-use. Any parts with heavy soiling can be reused after cleaning instead of discarded and replaced.

Reskinning

This is a specific process for laptops and again is a cosmetic repair. Sometimes it’s simply the outermost layer of a laptop shell that has suffered minor damage. Rather than replacing the whole component, reskinning enables the removal and refit of the damaged layer.

Keyboards and buttons are also tested and replaced if found faulty to ensure the next user has a seamless experience.

LCD repair

While a repair that’s not specific to Liquid Crystal Display screens only, and applicable to all kinds of light-emitting screens on devices, this technique combats heavier screen damage. Removing the top parts of a screen layer that have been damaged by chips or cracks, avoids a complete screen replacement.

Screens are often expensive and use several raw materials to manufacture. As one of the biggest damages that smartphones face, this practice cost-effectively and sustainably provides an alternative to scrapping the device.

Routes to recovery

Many electronic product types lend themselves to repair and refurbishment techniques, including but not limited to:

- Smartphones

- Tablets

- Laptops

- Earbuds

- Smartwatches

- Air fryers

- Coffee machines

- Gaming consoles

- Hairdryers

- Vacuum cleaners

These can all be collected from the user when they no longer have a use for them. These products may have lived out their current use with the owner or are perhaps no longer wanted for a different reason. As such, there are several ways where products may be returned to a retailer, manufacturer, insurer, or other company where they can be processed.

Returns management

There are several reasons why consumers signal their desire to return a product, such as:

- Change of mind within the cooling-off period

- Fault

- Upgrade issued

- The lease contract has ended

- No longer has a use for it within the returns period

Under the terms and conditions of sale or warranty, these products are typically returned to the original point of sale. This provides a large volume of products that may only be out of the box, need a small refurbishment, or need a root cause analysis to dive deeper into a fault.

These need efficient handling to minimize the negative impacts these returns have on the business. The product returns take up space, particularly products like coffee machines, vacuum cleaners, etc. Also, the longer they’re stored, they depreciate, lowering the potential value recovery.

Completing repair and refurbishment practices on these products removes the risk of them becoming e-waste. Through offering a robust returns management program, products are sustainably processed to enable the reuse of parts or the complete unit.

Trade-in and buyback

As the popularity of refurbished and second-hand products is increasing, trade-in and buyback programs are a great source of stock. These products provide an alternative for customers to purchase brand-new products. This may be for economic, accessibility, or environmental reasons.

Trade-in programs are typically consumer-facing, offering cash back for single units. Buyback programs are conducted on a bulk level, buying a fleet of assets, such as laptops or mobile phones, from an enterprise.

These schemes provide an incentive for the current owner of a product to return these for cash or store credit. Once ownership of the product is passed over, it can be sustainably processed for resale, parts harvesting, or recycling.

Depot services

These services are aimed specifically at enterprise customers and involve the bulk processing of end-of-life IT assets, such as laptops and mobile phones. This can include IT asset disposition (ITAD), the compliant destruction of IT equipment.

Depending on the level of sensitivity of the data that’s been housed on data-bearing devices, these may be suitable for wiping and asset resale. Where information is highly sensitive, data storage units are shredded, and the waste is managed responsibly.

Depot services include asset management, where IT refresh cycles are monitored, recovering devices, and when necessary, updates and upgrades are due. Devices are deployed and recovered from out in the field when an employee is onboarded or departs from the company.

Keeping on top of a device's status, including age, enables a more sustainable relationship, with software updates enhancing performance and keeping the products working for longer. This means that assets won’t be refreshed until necessary.

Reducing the environmental impacts of technology

Through these various means of technology collection and retrieval, tactics can be deployed to recover the working condition, extending product lifecycles. By restoring these products to a usable condition, it creates a supply that can be used as an alternative to buying brand-new technology.

This reduces the environmental impacts of our technology consumption. Avoiding the purchase of new technology reduces the pressure on manufacturing so fewer raw materials are harvested and less CO2 is released as a result.

This doesn’t just apply to whole products, but components too. Through reclaiming products, you can create an inventory of harvested parts to use in the extension of lifecycles instead of new components.

With less technology being discarded, less becomes e-waste for informal handling or environmental damage. It also creates financial opportunities for businesses in the recommerce of assets or avoidance of purchasing brand new technology where used becomes a suitable alternative.

Ready to improve your technology recovery?

Technology doesn’t have to become waste. There’s the saying that one man’s trash is another man’s treasure and it absolutely can apply here, in the modern age. With the help of industry insight, technical know-how, and expert processes, your business can shift from a linear technology consumption to a circular one.

Ingram Micro Lifecycle offers a complete package of end-to-end solutions for the recovery of high-end consumer electronics, IT and mobility assets, wearables, gaming consoles, small domestic appliances, and more. We offer these services globally, reducing the logistics involved in shipping products between hubs. We can support you wherever you are or wherever your customers are.

Customer technology assets enter our programs as preloved and become re-loved. Our full transparency underpins our customer relationships, striving for maximum yields and highest recommerce values.

Get in touch if you’d like to discuss more about how Ingram Micro Lifecycle can support your business process its technology more sustainably.

Further reading:

- 7 reasons why consumers are switching from new to refurbished devices

- Switching supply from new to refurbished devices? 5 key questions

- 5 sourcing pitfalls to avoid when stocking refurbished electronics

- 8 pitfalls of consumer-facing trade-in programs and how to avoid them

- Device trade-in success: the role of seamless customer experiences

- 8 ways 3PL transforms reverse logistics for a circular economy