Struggling with your reverse logistics program for small domestic appliances with high volumes and a lack of agility? You may witness a negative impact on your cost efficiencies, customer service, and brand reputation, among others.

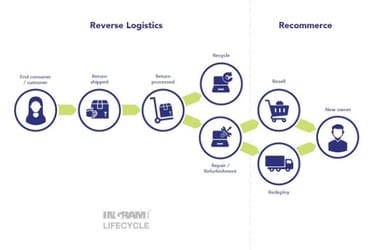

Ingram Micro Lifecycle works with global brands, retailers, and Original Equipment Manufacturers (OEMs) to manage returns of various high-tech electronics, including Small Domestic Appliances (SDAs).

Below, we shed some light on the issues we see in reverse logistics for SDAs and point you toward some solutions.

The problems facing OEMs and retailers for Small Domestic Appliances

Returns management is an inevitable part of sales. You cannot please everyone or predict factors such as change of mind or changes of circumstance. For example, a quarter of consumers are returning more online purchases than usual because of increasing economic pressures.

With more and more people working from home, it’s no surprise that the UK small domestic appliance market is expected to grow in the next five years from $3.9bn to $5.2bn. This increase in sales will naturally increase product volume within the reverse supply chain.

Here are seven key problems that we’ve identified with reverse logistics of SDAs and methods to solve these pain points.

Problem 1: Product condition

When managing the return of any product type, you may experience a diverse range of conditions when receiving the products back. These may be incorrectly used products (possibly not faulty), mechanical damages, and incomplete sets (perhaps an item was missed from the shipment or hasn’t been returned).

If you’re aiming to reduce waste and salvage parts or repair the product for recommerce, you need access to a variety of spare parts and manuals to ensure that the full scope of problems can be rapidly solved with the appropriate parts.

Solution: You need to organize and maintain a parts inventory to enable the repair of returned products.

Retailers need access to OEM parts and repair processes via accreditations. These ensure that repairs are conducted to a manufacturer-approved standard, using genuine parts. If you’re outsourcing returns management, ensure the partner you’re using is accredited for the appropriate OEM.

Gaining a thorough understanding of the product and its intricacies can be harnessed through product strip-downs and root-cause analysis.

To manage incorrect use or misunderstanding of instructions, feedback from return handlers should be passed to the customer service team. They can better understand the issues that customers face and how to respond to customer feedback. When a customer gets in touch because there's a product performance or function issue, the customer services team has an insight into the common issues customers have with interacting with the product.

Problem 2: Space

Products can take up a lot of space, particularly Small Domestic Appliances such as vacuums. The volume of space they consume can increase quickly if you aren’t processing the returns rapidly enough.

Solution: Without the space to keep up with the volume of returns, seeking a third-party partner will allow you to extend the space you have available without taking on the additional risks associated with new premises.

The partner should have the agility to flex with the ebbs and flows of seasonal returns and have the infrastructure and skilled technicians to process at scale and with speed.

Problem 3: Lack of recommerce opportunities

So, you’ve processed the returns. Now what? Minimizing your waste should mean that you see your processed returns as a revenue stream. But you need an outlet to quickly and efficiently monetize your stock. You may not have the network to support these activities which means stock will depreciate on your balance sheet.

Solution: Look for a returns management or aftermarket sales partner that has both the returns processing ability and a fully embedded recommerce team to get products back out to market, recovering value for you. The better their repair and refurbishment services, the better the condition and quality they can restore to the returns. Higher quality uplift equals higher value recovery.

Problem 4: Different test and repair requirements

If you have different facilities handling returns, you may experience a clash of processes and testing patterns. This can lead to inefficiencies as technicians process returns against different criteria and at differing speeds. Repairs will be conducted to a mix of standards, following different quality standards.

This is also the same if you work with different return partners in different areas.

Solution: You need to centralize your returns process. Manage your team under one set of guidelines, one process, and one list of criteria, with all facilities using the same equipment. Alternatively, it means working with one partner with a footprint covering all your areas of operation.

Problem 5: Diversity of products

With Small Domestic Appliance returns management, you could be handling vacuum cleaners, coffee machines, and hair dryers, as examples, all under one roof. This poses the challenge of having a breadth of technical understanding across the full product range. The process that’s needed to repair a hair dryer won’t be the same that’s required for a coffee machine.

You also may find that what fixes the hair dryer from Brand A is not the same as what fixes a hair dryer from Brand B. You need different manufacturer components and repair manuals.

Solution: A returns center will use training manuals produced by the OEM and will have the technical know-how to try their hand at a vast range of devices. This way, the technicians who handle the products have an intimate knowledge of a breadth of products. OEM accreditations ensure you have access to manufacturer-approved processes, genuine parts, instruction manuals, and repair guides.

If this isn’t possible with the staff, resources, or equipment that you have, then look for a returns management partner.

Problem 6: Time

Nobody has a time-turner or a time machine so unless you manage your time efficiently, it can quickly slip away from you and impact product depreciation. This means that you need to process returns rapidly to save a backlog forming and to recover as much value as possible from recommerce opportunities.

Seasonality also plays a part. Consider if your product falls into higher demand at a specific time of year. If your returns processing for that product ends up outside that window, you’ve potentially lost the opportunity to recover maximum value. Demand will have fallen and so will the price you can achieve on the secondary market.

Solution: Staying efficient with your process is key. You need technicians that are skilled and capable in their role. Introduce automation to streamline the process, minimize the margin for error, and reduce human bias. Equip your returns center with the correct tools, equipment, instruction manuals, and spare parts so the process flows smoothly, without interruption.

Problem 7: Agility

If you manage to keep on top of all the problems above, you still need the flexibility to ramp up and downsize as and when your volumes increase around seasonality. You need to stay efficient year-round. What’s your contingency plan should there be a supply issue so your return volumes drop? What if there’s a supply issue with the repair components you need?

Solution: Working with a returns management partner alleviates the pressure of managing returns. They have the agility to increase and decrease space as needed, plus have the contacts and network to maintain flexibility on parts supply outside of parts inventory.

Alleviate your returns management problems

There are a variety of issues that can arise from poorly managed returns if you don’t stay agile and efficient, including creating a backlog for processing, having the technical know-how to process a breadth of products, and failing to monetize returns as a revenue stream. One solution for a range of problems is to outsource your returns handling to a third-party returns management partner.

Ingram Micro Lifecycle has a global footprint with returns centers around the world. Our end-to-end processes ensure that products are assessed and graded rapidly before moving on to our repair and refurbishment solutions to maximize the potential value recovery across our secondary market network.

If you’d like to find out more, check out our further articles below or reach out to our team for a no-obligation discussion on how we can tailor our solutions to fit your needs.

Further reading:

- 11 benefits of returns management for Small Domestic Appliances

- 5 factors that affect product depreciation

- 9 key reverse logistics factors that affect value recovery

- Tips for getting the most from your returns management partner

- 7 ways to optimize technology reverse logistics

- 8 ways a tech reverse logistics partner enables a circular economy

- 9 technology industry & reverse logistics certifications

-1.jpeg?width=450&height=250&name=sda%20user-min%20(1)-1.jpeg)