Unsure of how switching to a circular economy could benefit you and your business? Want to make your business more sustainable, boosting your Environmental, Social, and Governance (ESG) objectives, but need more information on how to progress?

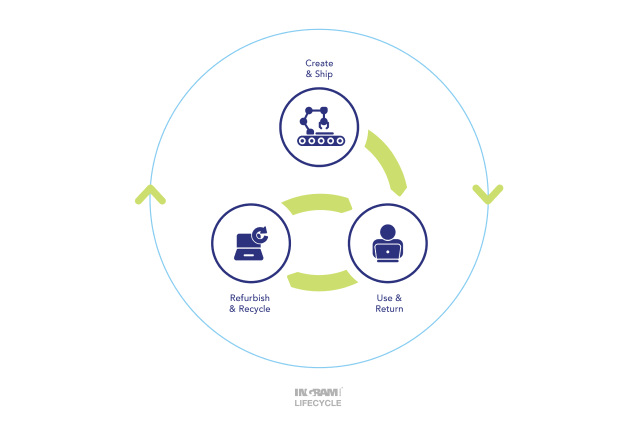

Ingram Micro Lifecycle has curated and honed a set of services that work to enable a circular economy for our customers. Working in harmony, our solutions underpin the complete lifecycle of your IT estate and technology products ensuring they retain as much value and use for as long as possible.

Throughout this article, we’ll detail the benefits of moving away from a linear economy to a circulaone. You’ll understand the advantages of a circular economy for your technology and be confident in the sustainability outcomes.

What is a circular economy?

A circular economy strives to extend the lifecycle of products already in circulation for as long as possible. This is a shift away from the current make, take, waste approach of the linear economy we’re used to.

Technology is repaired and refurbished for as long as economically viable to ensure less manufacturing is needed and the product has a longer life.

6 ways circularity is beneficial

We’ve previously explored how a circular economy differs from the linear approach that has been the norm.

While sustainability outcomes are one of the benefits, there are others too, making it a viable proposition for businesses.

1. Cutting carbon emissions

Consider the production levels required to manufacture a new device and the logistics behind it to get all the componentry together and shipped out to the end user.

Manufacturing technology contributes to over half of the world’s CO2 emissions.

By extending the lifecycle of technology when it becomes obsolete, the amount of new technology required and production will decrease, cutting carbon emissions.

2. Reducing toxic waste

A lot of e-waste is processed incorrectly, by open-air burning, through acid baths, and via personal handling of contaminants. This releases harmful substances such as lead, mercury, arsenic, and brominated flame retardants (BFRs).

Sustained human contact with these can cause neurological damage and cancer. These processes emit CO2 into the atmosphere.

E-waste makes up 2% of overall solid waste, which is equivalent to 70% of total hazardous waste.

Extending the lifecycle of devices will ease the pressures on e-waste processing facilities, remove the burden of informally handling it, and encourage recycling or safe destruction. Salvaging parts of

truly obsolete technologies and reusing them to extend the life of other devices will also decrease the number of materials going to waste.

3. Decreased consumption of natural resources

Manufacturing puts a strain on natural resources. With finite resources diminishing, harvesting reusable parts of obsolete technologies will ease some of this pressure. For example, due to refining, the precious metals found in printed circuit boards (PCBs) are 10 times more abundant than in the natural ores they were mined from.

The WEF reported in 2019 that over 92 billion tonnes of materials had been extracted and processed by the whole manufacturing industry.

Recycling tech allows some valuable raw materials such as indium, cobalt, and neodymium to be harnessed - these would otherwise be lost through e-waste, and sourcing the raw replacements would add to greenhouse gases (GHG).

Using analytic tools and systems, you, or a recycling partner, will be able to produce data that demonstrates the carbon emission reductions and material reuse/recycling for your business. These can be used within Board or company reports, enabling you to meet ESG targets.

4. Value return

With the environmental and economic benefits of extending the lifecycle of devices, there’s a huge opportunity to securely wipe devices that are perceived as obsolete to assess for value.

Going through the repair and refurbishment process will restore the condition of the device and increase its value, making it suitable for resale, thus recovering more value.

The value of the recommerce market is expected to increase to $51 billion in 2023.

Funds obtained from reselling technology can be used to funnel back into other business functions or bolster the data security budget. Alternatively, you could consider donating this to a charity and make additional progress with your ESG objectives.

5. Reducing downtime

One effective strategy for reducing downtime in businesses is to maintain a stock of refurbished devices. This ensures that an immediate replacement can be sent to employees when a faulty device is identified.

Meanwhile, the faulty device can be swapped and returned for screening and repair. This approach is advantageous for both on-site and remote workers, as it minimizes delays associated with sourcing replacements or waiting for device repairs.

By having a ready stock of devices on hand, businesses can streamline their operations and minimize disruptions caused by device failures.

6. Lifecycle management

When reusing technology or obtaining refurbished devices instead of new ones, working with a lifecycle partner ensures that the quality and standard of the equipment is maximized. The operating system and security software will be up-to-date, and the device will be running the latest software.

This is all configured and optimized before being despatched to you or your employees, aiding in minimizing staff time required for these operations. Getting set up and work started is as smooth as possible from a technology perspective as everything is prechecked and ready to go.

Devices can be preconfigured to a set list of requirements. For example, certain web addresses can be blocked, company-branded display background loaded, and specific software or apps installed.

With this lifecycle partnership also comes warehousing for your assets. Inventory tracking will be readily available for you to see which assets are deployed and call them off for use. Devices will be data-wiped and kept compliant with data security policies and regulations, providing you peace of mind.

Ready to start your circular journey?

The services outlined above fit into three key processes: reuse, resell, and recycle.

Ingram Micro Lifecycle’s mission is to enable a circular economy for our customers. We work with those within the technology industry to provide lifecycle management solutions, including asset management, repair and refurbishment, field services, reselling, and other value-added services.

Get in touch with us to discuss how we can tailor our services to enable a circular economy for you.

Related reading

- Circular economy 101: moving beyond linear models

- 8 ways 3PL transforms reverse logistics for a circular economy

- 8 ways a tech reverse logistics partner enables a circular economy

- 4 ways a circular economy has influenced device ownership

- 5 ways a technology circular economy boosts your sustainability goals

- How can your business reduce corporate e-waste in 2023?

.jpg?width=450&height=250&name=used%20computer%20hardware%20in%20garbage%20(1).jpg)